Electronics Assembly Applications | Precision Linear Motion Systems

High-performance linear guides, ball screws, and linear modules designed for electronics assembly equipment and SMT automation.

Precision Motion Systems for Electronics Assembly

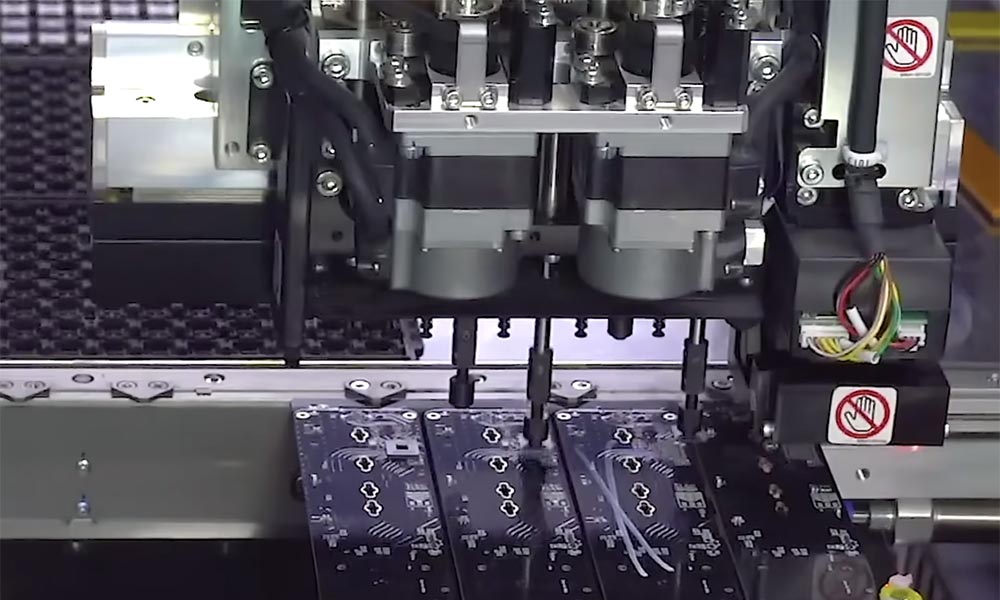

The electronics assembly industry depends on automation systems that perform with extreme precision and reliability. In surface-mount technology (SMT) lines, dispensing systems, and automated soldering machines, the difference between success and failure can be measured in microns. High-speed pick-and-place heads, conveyors, and inspection systems must move smoothly, consistently, and repeatably — often operating 24 hours a day.

At the core of these systems are linear motion components that guide, position, and support every motion axis. Motiontek’s linear guides, ball screws, and linear modules are designed to provide the accuracy, rigidity, and durability required for electronics manufacturing environments. They ensure stable motion even under dynamic loads, frequent starts and stops, and long operating cycles.

The Role of Linear Motion in Electronics Assembly

1. High-Speed Placement Accuracy

Modern pick-and-place machines operate at over 50,000 components per hour, requiring exceptional accuracy in the X/Y axes. Even minor deviations can cause misalignment of micro-sized components. Motiontek linear guides and ball screws provide the tight tolerances and low vibration necessary to achieve reliable placement on densely packed PCBs.

2. Smooth and Repeatable Movement

Dispensing, gluing, and soldering operations demand smooth transitions and stable acceleration. Any mechanical jerk could result in uneven adhesive application or solder bridging. Our precision-ground linear rails ensure low friction and smooth travel, supporting consistent results even at high throughput.

3. Clean and Stable Motion for Optical Systems

Electronics inspection and AOI (Automated Optical Inspection) systems require clean, noise-free motion for stable image acquisition. Motiontek linear modules deliver near-zero backlash and high stiffness, enabling precise scanning for quality control.

Linear Guides in PCB Assembly and SMT Lines

1. Supporting Multi-Axis Motion

Linear guides serve as the foundation of gantry systems that control X, Y, and Z axes in pick-and-place, screen printing, and test equipment. The preloaded contact structure eliminates clearance and maintains high rigidity under rapid acceleration.

2. Compact and Lightweight for Speed

Our miniature linear guides are ideal for small-format assembly systems and compact equipment, offering a balance between weight reduction and mechanical strength. Lightweight aluminum or stainless-steel components reduce inertia and enhance positioning speed.

3. Corrosion and Dust Resistance

Electronics assembly often takes place in controlled environments that demand cleanroom compatibility and anti-corrosion materials. Motiontek offers stainless-steel and low-particulate versions of its guides, suitable for sensitive production areas.

Ball Screws for Precise Positioning

1. Z-Axis Control for Placement Heads

Pick-and-place heads and dispensing nozzles rely on accurate Z-axis control. Our precision-ground ball screws convert rotational motion into linear movement with micron-level repeatability, ensuring consistent component height and solder paste deposition.

2. Smooth Start–Stop Operation

The internal circulation design of Motiontek ball screws minimizes vibration and noise during frequent start–stop cycles. This is critical for fine-pitch component placement and reduces mechanical stress on motors and couplings.

3. Long Service Life and Minimal Maintenance

Electronics assembly machines run continuously for thousands of hours. Motiontek ball screws are engineered for extended duty cycles, with heat-treated raceways and optimized lubrication systems that reduce maintenance intervals.

Linear Modules for Integrated Motion Systems

For OEM designers looking to simplify mechanical integration, Motiontek provides linear motion modules — fully assembled units combining linear guides, ball screws, and drive systems. These modules reduce assembly time, improve system consistency, and enhance repeatability across production lines.

Advantages:

- Plug-and-play motion units for single or multi-axis automation

- Compatible with servo and stepper motor interfaces

- High-speed travel with low vibration and noise

- Configurable stroke lengths from 100 mm to 1200 mm

- Factory preloaded for zero-backlash motion

These linear modules are widely used in solder paste printers, glue dispensers, cutting machines, and component placement systems, enabling fast setup and minimal maintenance.

Engineering Considerations in Electronics Manufacturing

| Motion Requirement | Technical Challenge | Motiontek Solution |

|---|---|---|

| High-speed precision | Vibration and positional drift | Preloaded linear guides with smooth travel |

| Long duty cycles | Wear and lubricant breakdown | Heat-treated rails and self-lubricating blocks |

| Tight space constraints | Compact mechanical design | Miniature linear guides and modules |

| Dust and residue | Contamination on raceways | Sealed and stainless-steel guide options |

| Noise reduction | Sensitive testing environments | Silent internal circulation design |

Motion Control in Common Electronics Assembly Systems

SMT Pick-and-Place Machines

Linear guides and ball screws move placement heads with micron-level precision across X, Y, and Z axes, ensuring accurate placement at high speed.Screen Printing and Solder Paste Equipment

Linear motion modules provide stable stencil movement and scraper alignment, ensuring even paste application and long-term accuracy.Dispensing and Conformal Coating Systems

Motiontek systems ensure uniform motion for adhesive or coating application, achieving consistent film thickness and coverage.Reflow and Wave Solder Conveyors

Ball screws and linear rails guide conveyor mechanisms, ensuring stable board transfer through high-temperature zones.Automated Test Equipment (ATE)

Precision movement of probes and fixtures relies on low-friction linear guides for accurate electrical contact and measurement repeatability.Laser Marking and Inspection Systems

Linear modules with optical feedback enable smooth scanning motion for high-resolution marking and inspection accuracy.

Benefits of Motiontek Linear Motion Components in Electronics Assembly

- High-speed precision motion for micro-scale component handling

- Long service life under continuous operation

- Compact and lightweight structure suitable for dense machine layouts

- Silent operation compatible with cleanroom environments

- Corrosion-resistant materials for extended durability

- Custom integration support for OEM equipment builders

Each Motiontek component undergoes strict quality inspection to ensure reliability and long-term stability under dynamic load conditions.

Quality, Cleanliness, and Traceability

In electronics manufacturing, cleanliness and consistency are critical. Motiontek ensures every linear guide and ball screw is assembled in a controlled environment and inspected using digital measuring systems.

We provide full lot traceability, ISO-compliant documentation, and lubrication certifications to meet international cleanroom standards.

With our advanced CNC production and automated inspection lines in Shenzhen, Motiontek can deliver large-volume OEM orders with consistent accuracy, helping customers streamline production and reduce downtime.

Future of Motion in Electronics Manufacturing

As the electronics industry moves toward miniaturization, 5G devices, and flexible circuit assembly, precision motion requirements are becoming even more stringent.

Motiontek is investing in smart linear motion modules with embedded sensors for real-time position feedback and automatic condition monitoring.

These intelligent systems will enable predictive maintenance, improved reliability, and reduced unplanned downtime in high-volume production lines.

Why Choose Motiontek for Electronics Assembly Systems

- Expertise in precision motion engineering

- Wide product portfolio: linear guides, ball screws, linear modules

- Customizable stroke lengths, preload options, and materials

- Proven reliability in global electronics manufacturing lines

- Dedicated engineering support and responsive lead times

From SMT lines to optical inspection platforms, Motiontek delivers the motion control foundation that powers modern electronics production.