What Is Linear Guides? | Understanding Linear Motion Systems

Learn what linear guides are, how they work, and why they are essential for industrial automation, CNC machines, and robotics.

Introduction: What Is a Linear Guide?

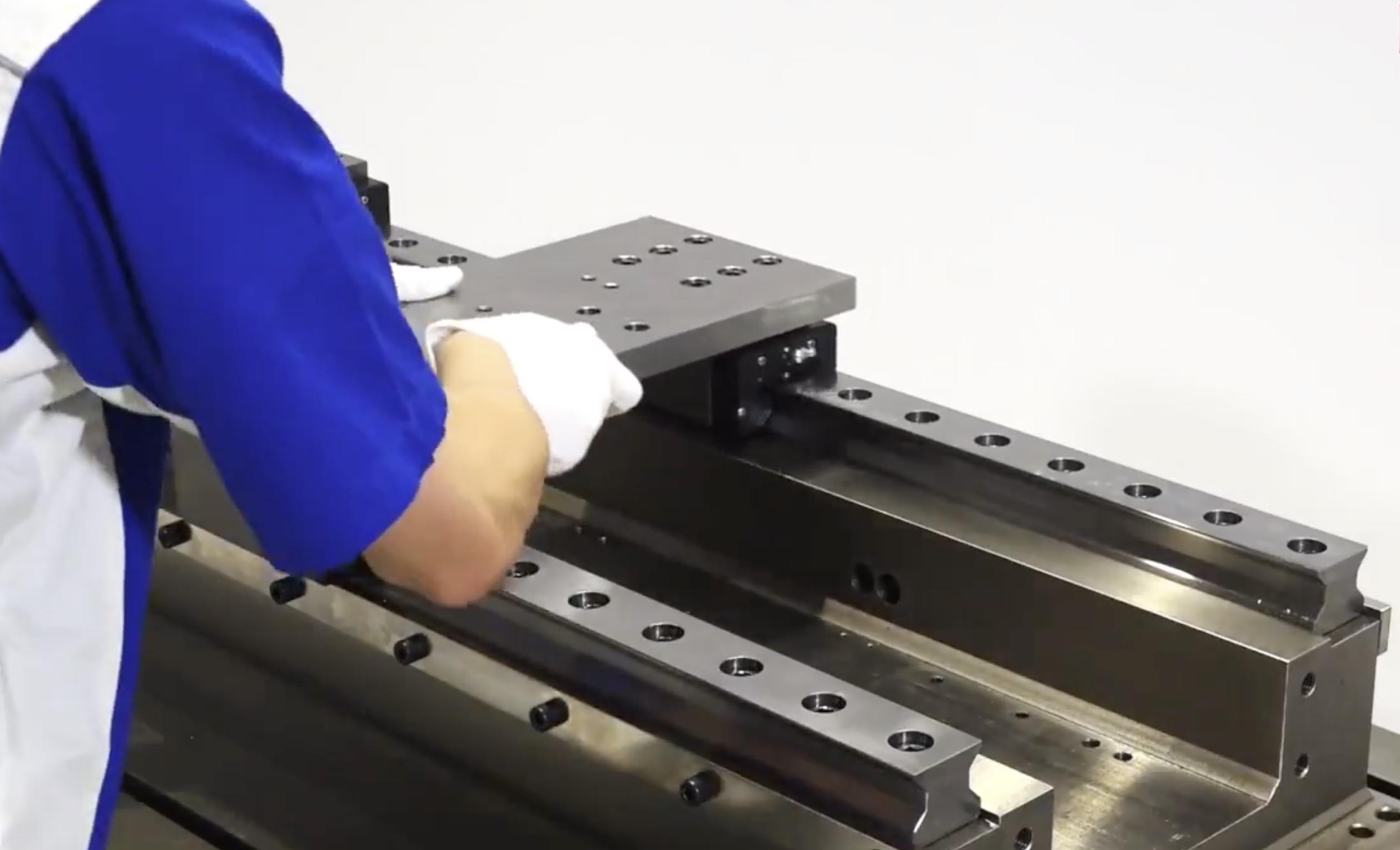

A linear guide, also known as a linear guideway or linear bearing, is a mechanical system designed to provide smooth and precise linear motion.

Unlike traditional sliding contact mechanisms that rely on friction between surfaces, linear guides use rolling elements such as balls or rollers between a rail and a block.

This design minimizes resistance, ensures stable movement, and allows for high repeatability, even under heavy loads.

In simple terms, a linear guide converts rotary motion into straight-line motion while maintaining accuracy, stiffness, and low wear.

This makes it a core component in a wide range of industrial equipment—from CNC machine tools and pick-and-place robots to 3D printers, medical instruments, and semiconductor automation.

Working Principle of Linear Guides

The linear guide consists of two primary components:

- Guide Rail – a precisely ground steel track fixed on a base.

- Guide Block (Carriage) – a sliding block that runs along the rail, containing rolling elements such as steel balls or cylindrical rollers.

Between them, recirculating rolling elements (balls or rollers) move along defined tracks.

The contact angle and preload design ensure uniform load distribution across four directions—radial, reverse radial, and lateral—enabling smooth motion with minimal deflection.

When the block moves, the rolling elements circulate inside the block housing through an internal or external loop, returning to their starting position continuously.

This recirculating mechanism is why linear guides are often categorized as internal circulating or external circulating systems.

Structure and Components

A typical linear guide assembly includes the following elements:

| Component | Function |

|---|---|

| Guide Rail | Provides a hardened track for rolling elements |

| Guide Block | Houses the rolling elements and transfers load |

| Rolling Elements | Balls or rollers that provide low-friction motion |

| End Cap & Return Tube | Guide the rolling elements in a continuous loop |

| Retainer | Prevents the balls from falling out when the block is removed |

| Seals and Scrapers | Keep out dust, chips, and coolant to extend lifespan |

For high-end industrial applications, manufacturers often apply surface hardening treatments, anti-corrosion coatings, and precision grinding to ensure longevity and consistent accuracy.

Types of Linear Guides

Linear guides come in several designs depending on the load, speed, and accuracy requirements:

1. Linear Ball Guides

The most common type.

They use steel balls as rolling elements, offering excellent smoothness and low friction.

Ideal for applications where precision and moderate load capacity are required.

2. Linear Roller Guides

These use cylindrical rollers instead of balls.

Because rollers provide a larger contact area, they deliver higher stiffness and load-bearing capacity, suitable for machine tools, presses, and heavy automation.

3. Miniature Linear Guides

Designed for compact devices like 3D printers, optical instruments, and semiconductor equipment.

They provide high precision in limited spaces and are often made of stainless steel for corrosion resistance.

4. Flanged or Compact Types

Flanged blocks simplify installation, while compact types save space.

Both maintain full interchangeability with standardized rail dimensions (e.g., sizes 15–65 mm).

Advantages of Linear Guides

Linear guides offer multiple benefits compared with conventional sliding motion systems:

High Precision and Repeatability

Rolling contact reduces friction to less than 1/50 of sliding contact, maintaining micron-level accuracy.Long Service Life

Hardened tracks and even load distribution prevent wear, extending operational lifespan.High Rigidity

Four-direction equal load design enhances stiffness and minimizes vibration.Energy Efficiency

Minimal friction means less power loss and smoother drive response.Easy Maintenance

Simple lubrication and built-in wipers ensure long-term operation with minimal upkeep.Modular Design

Interchangeable blocks and rails simplify replacement and upgrades.

Linear Guides vs. Traditional Slide Rails

| Feature | Linear Guides | Slide Rails |

|---|---|---|

| Motion Type | Rolling | Sliding |

| Friction Coefficient | Very Low | High |

| Precision | High (micron level) | Moderate |

| Load Capacity | High, multi-directional | Limited |

| Durability | Excellent | Shorter lifespan |

| Maintenance | Easy | Frequent lubrication required |

| Typical Applications | CNC, robotics, automation | Basic motion mechanisms |

Linear guides clearly outperform conventional slide rails in terms of accuracy, longevity, and efficiency—which is why they dominate today’s automation and robotics industries.

Applications of Linear Guides

Because of their precision and reliability, linear guides are widely used in industrial equipment and automation systems, including:

- CNC machine tools

- Robotic arms and automation lines

- Semiconductor manufacturing

- Medical and laboratory instruments

- Inspection and measurement equipment

- 3D printing and additive manufacturing

- Packaging and assembly machines

In these applications, the linear guide ensures smooth, vibration-free, and repeatable motion, essential for precision manufacturing.

Selecting the Right Linear Guide

When selecting a linear guide, engineers typically consider:

Load Capacity and Direction

Whether the load acts vertically, horizontally, or from multiple directions.Accuracy Requirements

Choose appropriate preload and precision grades depending on tolerance needs.Speed and Stroke Length

Longer strokes or high-speed movement require stronger rigidity and stable lubrication.Environmental Conditions

In dusty or corrosive environments, stainless-steel rails and seals are recommended.Installation Space

Miniature or compact linear guides are used when space is limited.Budget and Lead Time

Cost-effective configurations can be achieved with standardized Motiontek series models.

Maintenance Tips for Longer Lifespan

- Apply suitable lubrication regularly to reduce wear.

- Install end seals and scrapers to prevent debris contamination.

- Avoid misalignment during installation—parallelism errors can lead to uneven wear.

- Periodically inspect preload and mounting torque.

- Store in dry conditions to prevent corrosion before assembly.

Proper maintenance can extend the service life of linear guides by several times, maintaining accuracy and reliability.

Motiontek Linear Guides: Precision You Can Trust

Motiontek provides a full range of linear guides, ball screws, and linear modules for industrial automation and OEM equipment.

Our linear motion systems are engineered for micron-level accuracy, high rigidity, and customizable specifications to match your design needs.

Whether you are designing a CNC machine, a robotic arm, or semiconductor handling equipment, Motiontek’s linear guide solutions deliver stable performance, long-term reliability, and flexible customization.

Explore our product categories:

Conclusion

Linear guides are the backbone of modern precision machinery.

Their ability to provide smooth, low-friction, and highly accurate linear motion makes them indispensable in today’s automation, robotics, and manufacturing industries.

By understanding their structure, working principles, and benefits, engineers can select and implement the right linear motion solutions to achieve stable, high-efficiency production.

If you are looking for a reliable supplier of linear guides and motion systems, contact Motiontek for technical consultation and OEM customization.

Further Reading